Technical parameters Products are classified | Model | Average particle size (nm) | Purity (%) | Specific surface area (m 2 / g) | Bulk density (g / cm 3) | Polymorphs | Color | Nanoscale | DK-AlN-001 | 50 | > 99.9 | 42.0 | 0.15 | The six-party | Gray White | Submicron | DK-AlN-002 | 500 | > 99.9 | 12.9 | 1.15 | The six-party | Gray |

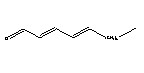

The main characteristics of nano-aluminum nitride ultrafine nitride aluminum powder prepared through a special process, high purity, small particle size, specific surface area, surface activity, surface modification of powder, not the hydrolytic reaction with oxygen is very low (<0.1%), thermal insulation performance effect is very obvious. In the polymer resin, tackifying obvious, is the best thermal insulation filler. Nano-aluminum nitride is a diamond-like carbon nitride, the maximum stability to 2200 ° C, high strength at room temperature, and the intensity decreases slowly with increasing temperature; nano nitride aluminum body with good thermal conductivity, thermal expansion coefficient, thermal conductivity 320w/mk rate theory of value and copper almost the same time, highly insulated, the resistivity above 10 ^ 15, and can withstand 1,400-degree heat, can significantly improve the thermal conductivity of plastic and silicone rubber, is a good resistance to thermal shock of materials, the ability of erosion resistance to molten metal is cast iron, aluminum or aluminum alloy ideal crucible material; nano-aluminum nitride with excellent electrical insulating properties, good dielectric properties; nano aluminum nitride has a good injection formability; for composite materials, semiconductor silicon matching, interface compatibility, can improve the mechanical properties and thermal conductivity of the composite dielectric properties.

Applications

The manufacture of integrated circuit substrate, electronics, optics, heat sink, high temperature crucible fabrication of metal matrix and polymer-based composites, especially in the high temperature sealing adhesives and electronic packaging materials to improve thermal performance and strength characteristics of materials, has an excellent potential applications can replace the current import-micron aluminum nitride;

Two thermal silica and thermal conductivity of epoxy resin: I produced nano aluminum nitride prepared by ultra-high thermal conductivity of silicone, it has good thermal conductivity, good super electric insulation, wide electrical insulation and the use of temperature (working temperature of 80-250 ° C), lower consistency and good workability. Products has reached more than imported products, because it can replace similar imported products are widely used in electronic devices such as heat transfer medium, and improve work efficiency. Such as the CPU and heat sink gap, the power transistor, thyristor, diode, of the slit in contact with the substrate at the heat transfer medium. Nano thermal paste to fill the gap between the IC or transistor and heat sink, increasing the contact area between them to achieve better cooling;

3 nano-lubricants and antiwear agent: Nano ceramic oil added to the modified nano aluminum nitride ceramic particles inside the engine with lubricating oil acting on the friction pair of metal surfaces, high temperatures and under extreme pressure is activated, and solid infiltration embedded into the metal surface dents and microporous repair damaged surface, the formation of nano-ceramic protective film.Because the effect of isolation of this membrane, the relative movement between the friction generated in the parts only role in this layer of protective film, and nano-ceramic particles like small ball parts of friction between the friction pair from the traditional sliding friction into rolling friction, which greatly reduces the friction, the friction between the moving parts is reduced to almost zero play a superior anti-wear protective effect on the engine, by improving the lubrication, which reduces the friction coefficient of more than 80%, improve the abrasion resistance of more than 350% more than 80 percent, reducing wear and tear and prolong the mechanical parts life of more than three times, reduced downtime, lower maintenance costs, extending the overhaul period more than doubled, energy-saving 10% -30%, increase power output by 20% -40%, add it only two ten thousandths to one-thousandth;

High thermal conductivity plastic: modified nano-nitride aluminum body can significantly improve the thermal conductivity of plastics. Experimental products to 1% added to the plastic, so that the thermal conductivity of the plastic from 0.3 to 3, the thermal conductivity was increased by more than 10 times. Is mainly used in PVC plastic, polyurethane plastics, PA plastic, functional plastic;

Other application areas: nano-aluminum nitride can be applied to the crucible smelting non-ferrous metals and semiconductor materials, gallium arsenide, the evaporation boat, thermocouple protection tube, high temperature insulation, microwave dielectric materials, high temperature and corrosion resistance of structural ceramics and aluminum nitride microwave ceramics.

|