| CAS Nr:. | - | EINECS No.: | - |

| Khoom npe: | Silicon carbide hmoov | Qauv nab npawb: | NM-009 |

| Qhov tsos: | hmoov dub | Hom Lub Npe: | RWM |

| Cov duab: | Hmoov | Daim ntawv thov: | Kev lag luam |

| Qhov Loj: | 50nm ua | Khoom siv: | Silicon carbide hmoov |

| Tshuaj muaj pes tsawg leeg: | Silicon carbide hmoov | Purity: | 99.9% |

| Qhov Chaw Keeb Kwm: | Shanghai, Suav teb (Mainland) | Qhov nruab nrab particle loj (nm): | 40 |

| Qhov chaw tshwj xeeb (m 2 / g): | 39.8 ib | Qhov ceev (g / cm3): | 0.11 |

Peb muab siab purity ntawm Nano Silicon carbide hmoov.Kho kom haum cov khoom alloy raws li tus neeg yuav tsum tau muaj

| Cov khoom raug cais | Qhov nruab nrab particle loj (nm) | Purity (%) | Qhov chaw tshwj xeeb (m2 / g) | Qhov ceev (g / cm3) | Polymorphs | Xim |

| Nanoscale | 40 | > 99.9 | 39.8 ib | 0.11 | kub | celadon |

| Submicron | 600-800 | > 99.5 | 3.20 | 1.52 ib | kub | grey |

Cov yam ntxwv tseem ceeb

Ultrafine nano silicon carbide, silicon carbide hmoov los ntawm kev hloov pauv tam sim no laser ion beam, tshuaj vapor deposition los ntawm kev hloov pauv tam sim no, kev tawm hluav taws xob siab, tuaj yeem kov yeej qhov tsis txaus ntawm dc hluav taws xob arc (cov lus teb tsis txaus, cov khoom tsis zoo, cov khoom tsis zoo).High purity, me me particle loj tis, siab tshwj xeeb nto;Nano silicon carbide muaj cov tshuaj ua haujlwm ruaj khov, siab coefficient ntawm thermal conductivity (165 w / MK), thermal expansion coefficient me me, siab hardness, mohs hardness mus txog 9.5, microhardness ntawm 2840 ~ 3320 kg / yog thawj cov khoom abrasion resistant additives, nws hardness yog nruab nrab ntawm fused alumina thiab pob zeb diamond, txhua yam muaj zog yog siab dua fused alumina;Nano silicon carbide muaj thermal conductivity zoo heev, kuj yog ib hom semiconductor, muaj peev xwm ntawm kub oxidation kuj;Nano silicon carbide hnav-tiv taus, kub tsis kam, corrosion kuj, tsis kam mus rau acid thiab alkali hnyav, dav siv nyob rau hauv cov xim, xim, nce hnav tsis kam.

Kev thov

1 hloov kho siab zog nylon khoom: nanometer SiC hmoov nyob rau hauv cov ntaub ntawv polymer compatibility yog zoo, zoo dispersibility, thiab ua ke nrog zoo matrix, thiab hloov nylon alloy siab zog tensile zog los ntawm ntau tshaj 150% siab tshaj li ntawm PA6 zoo tib yam, hnav- tiv thaiv kev ua tau zoo nce ntau dua peb zaug.Feem ntau yog rau armored tracked tsheb polymer qhov chaw, tsheb kauj vab qhov chaw, textile machinery, mining machinery lining board, lub tsheb ciav hlau qhov chaw nyob rau hauv lub qis kub sintering densification yog mus txog;

2 hloov kho tshwj xeeb engineering yas polyether ether ketone (PEEK) hnav-tiv taus kev ua tau zoo: tom qab ua tiav ntawm nano silicon carbide, thaum ntxiv kom muaj nuj nqis yog kwv yees li 5%, tuaj yeem txhim kho tau zoo thiab nce qhov hnav ntawm PEEK (nce los ntawm ntau dua 30% );

3 ntawm daim ntawv thov ntawm nano silicon carbide nyob rau hauv cov roj hmab log: ntxiv 2% los yog li ntawm nano silicon carbide yam tsis tau hloov collagen hloov mis, thiab tsis txo nws cov kev ua tau zoo thiab zoo nyob rau hauv lub premise ntawm nws hnav kuj yuav nce los ntawm 20% - 40 %.Tsis tas li ntawd, daim ntawv thov ntawm nano silicon carbide hauv cov menyuam roj hmab, lub tshuab luam ntawv fuser zaj duab xis, xws li hnav tsis kam, kub, kub tsis kam thiab lwm yam khoom siv roj hmab;

4 nanometer SiC composite txheej hlau nto: nano-scale particles thib ob hybrid hais, npib tsib xee raws li cov matrix hlau, hlau nto los ua siab ceev, bonding zog zoo heev composite electrodeposition, hlau nto nrog ib tug nyuaj (hnav) thiab antifriction ( self-lubricating) kub resistant yam ntxwv.Zoo heev txhim kho cov txheej txheej microhardness, hnav tsis kam nce 2-3 zaug, txhim kho kev pab cuam lub neej ntawm 3-5 zaug, lub zog adhesion ntawm txheej thiab substrate nce 40%, npog lub peev xwm muaj zog, txheej txheej, du thiab muag heev;

5 lwm yam kev siv: cov qauv kev ua haujlwm siab ceramics (xws li foob pob hluav taws xob, kev lag luam nuclear, thiab lwm yam), absorbing khoom, hnav-resistant lubricating grease, high-performance nres pads, siab hardness, hnav tsis kam ntawm hmoov coatings, composite ceramic enhanced toughening , lwm.;Nyob rau hauv lub tshav pob ntawm aerospace kev lag luam qauv, functional txheej, tiv thaiv txheej, txheej absorbing cov ntaub ntawv, stealth cov ntaub ntawv, thiab lwm yam .;Tanks thiab armored tsheb tiv thaiv armor;Rau cov cuab yeej txiav ceramic, cov cuab yeej txiav thiab ntsuas cov cuab yeej thiab tuag;Raws li kev siv tshwj xeeb cov qauv ceramics, kev ua haujlwm ceramics, engineering ceramics;Hluav taws xob;Hluav taws xob muaj hluav taws xob cua sov ntsiab lus, deb infrared generator.

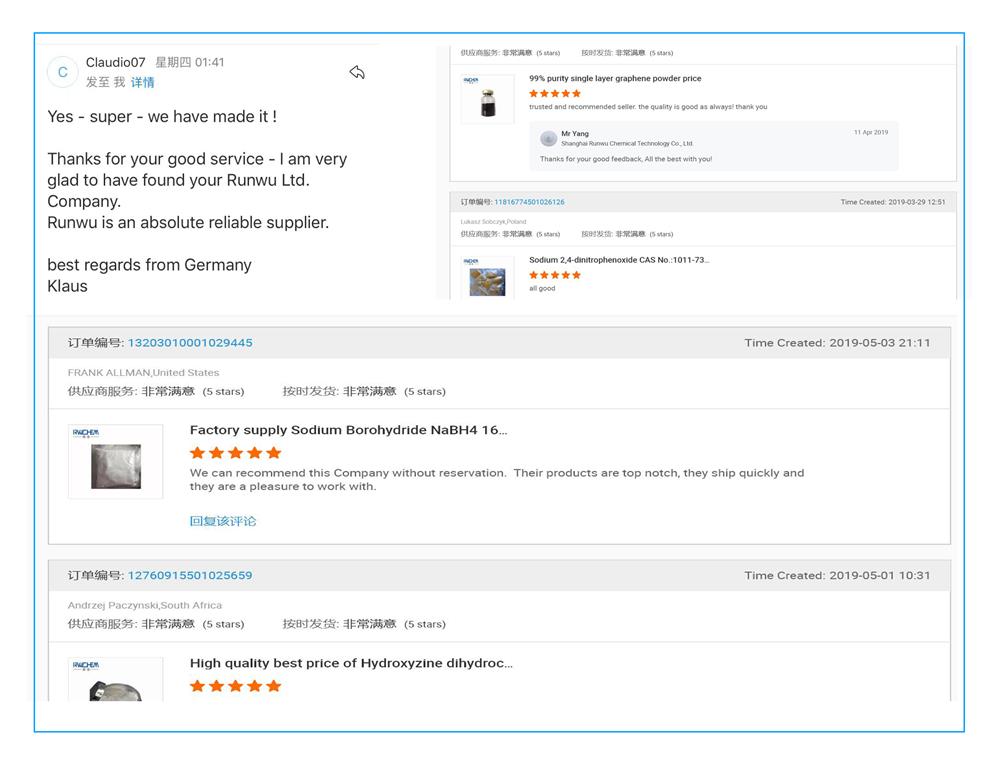

Shanghai Runwu Chemical Technology Co. Ltd yog cov khoom lag luam tshuaj lom neeg R & D, ntau lawm, kev muag khoom, ua ib qho ntawm kev tshawb nrhiav.Peb nyob ntawm kev muaj peev xwm tshawb fawb muaj zog thiab paub tab technology, muaj kev nce siab hauv kev lag luam tshuaj, vam khom rau kev tshawb fawb thiab thev naus laus zis, muab cov neeg siv khoom zoo tshaj plaws yog peb qhov kev nrhiav tsis tu ncua.

Peb tsuas yog cuam tshuam nrog cov organic intermediates, noble hlau catalyst, cov ntaub ntawv nano, tsis tshua muaj ntiaj teb.Cov ntaub ntawv no tau siv dav hauv chemistry, tshuaj, biology, kev tiv thaiv ib puag ncig, lub zog tshiab, thiab lwm yam.

Nrog thawj cov khoom lag luam zoo thiab cov kev pabcuam zoo tshaj plaws, Peb tau txais kev qhuas ntawm kev lis kev cai.Nyob rau tib lub sijhawm, hauv kev txhim kho, peb lub tuam txhab ua raws li kev koom tes nrog cov tuam txhab hauv tsev thiab txawv teb chaws, cov chaw tshawb fawb tshawb fawb, kev sib pauv hauv tsev kawm qib siab, txhawm rau txhim kho R & D thiab muaj peev xwm ntau lawm, cog lus los muab cov neeg siv khoom nrog cov khoom zoo thiab cov kev pabcuam.

Cov qauv dawb

Cov qauv dawb rau kev soj ntsuam zoo muaj

Hoobkas

Lub Hoobkas tshawb xyuas txais tos

Kev txiav txim

Kev txiav txim me me tau txais