| Nọmba CAS: | - | EINECS Mba: | - |

| Aha ngwaahịa: | Silicon carbide ntụ ntụ | Nọmba nlereanya: | NM-009 |

| Ọdịdị: | nwa ntụ ntụ | Aha ika: | RWCHEM |

| Ụdị: | Ntụ ntụ | Ngwa: | Ụlọ ọrụ mmepụta ihe |

| Akụkụ: | 50nm | Ihe: | Silicon carbide ntụ ntụ |

| Ngwakọta kemịkalụ: | Silicon carbide ntụ ntụ | Ịdị ọcha: | 99.9% |

| Ebe amụrụ: | Shanghai, China (Mainland) | Nkezi nha nha (nm): | 40 |

| Mpaghara elu akọwapụtara (m 2/g): | 39.8 | Nnukwu njupụta (g/cm 3): | 0.11 |

Anyị na-enye nnukwu ịdị ọcha nke Nano Silicon carbide powder.Adjust proportion alloy ngwaahịa dị ka ndị ahịa chọrọ.

| A na-ahazi ngwaahịa | Nkezi nha nha (nm) | Ịdị ọcha (%) | Mpaghara elu akọwapụtara (m2/g) | Njupụta nnukwu (g/cm3) | Polymorphs | Agba |

| Nanoscale | 40 | > 99.9 | 39.8 | 0.11 | cubic | celadon |

| Submicron | 600-800 | > 99.5 | 3.20 | 1.52 | cubic | agba ntụ |

Isi njirimara

Ultrafine nano silicon carbide, silicon carbide ntụ ntụ site na-agbanwe agbanwe ugbu a laser ion beam, kemịkalụ vapor deposition site na agbanwe ugbu a, elu voltaji mwepu, nwere ike zuru ezu imeri adịghị ike nke dc electric arc (azaghachi ezughị ezu, elu ngwaahịa adịghị ọcha, adịghị mma nkwụsi ike nke ngwaahịa).High ịdị ọcha, obere urughuru size nkesa, elu kpọmkwem elu ebe;Nano silicon carbide nwere arụmọrụ kemịkalụ kwụsiri ike, ọnụọgụ dị elu nke conductivity thermal (165 w / MK), obere ọnụọgụ mgbasa ọkụ, ike siri ike, ike siri ike nke mohs ruo 9.5, microhardness nke 2840 ~ 3320 kg / bụ ihe mgbakwunye na-eguzogide ihe mbụ abrasion, ike ya dị n'etiti alumina jikọtara ọnụ na diamond, ike arụ ọrụ dị elu karịa alumina jikọtara ọnụ;Nano silicon carbide nwere ọmarịcha thermal conductivity, bụkwa ụdị nke semiconductor, nwere ike na elu okpomọkụ ọxịdashọn iguzogide;Nano silicon carbide wear-eguzogide, elu okpomọkụ na-eguzogide, corrosion iguzogide, iguzogide acid na alkali mgbaze, ọtụtụ ebe na agba, agba, dịkwuo eyi nguzogide.

Ngwa

1 gbanwetụrụ elu ike naịlọn ihe onwunwe: nanometer SiC powders na polymer composite ihe ndakọrịta dị mma, ezi dispersibility, na jikọtara na ezi matrix, na gbanwetụrụ naịlọn alloy elu ike tensile ike karịa 150% elu karịa nke nkịtị PA6, wear- iguzogide arụmọrụ mụbara ihe karịrị ugboro atọ.tumadi maka akụkụ ndị a na-esochi ụgbọ ala polima, akụkụ ụgbọ ala ụgbọ ala, igwe textiles, igwe mkpuchi igwe, akụkụ ụgbọ oloko n'okpuru obere okpomọkụ sintering densification ruru;

2 gbanwetụrụ plastik injinia pụrụ iche polyether ether ketone (PEEK) na-eguzogide arụmọrụ: mgbe nhazi elu nke nano silicon carbide, mgbe ị na-agbakwunye ọnụọgụ dị ihe dịka 5%, nwere ike imeziwanye ma bulie wearability nke PEEK (amụbawanye karịa 30% );

3 nke ngwa nke nano silicon carbide na taya roba: na-agbakwunye 2% ma ọ bụ karịa nke nano silicon carbide na-enweghị agbanwe agbanwe usoro collagen, na-enweghị ibelata arụmọrụ ya na ịdịmma ya n'okpuru echiche nke nguzogide iyi ya nwere ike ịbawanye site na 20% - 40 %Tụkwasị na nke ahụ, ngwa nke nano silicon carbide na roba roba, ihe nkiri fuser nke ngwa nbipute, dị ka eyi iguzogide, okpomọkụ, okpomọkụ na-eguzogide na ngwaahịa roba ndị ọzọ;

4 nanometer SiC mejupụtara mkpuchi metal elu: na nano-ọnụ ọgụgụ ahụ abụọ ngwakọ ahụ, nickel dị ka matrix metal, na metal elu na-etolite elu njupụta, bonding ike dị mma mejupụtara electrodeposition, metal elu na a siri ike (yi) na mgbochi (eyi) onwe-lubricating) àgwà na-eguzogide okpomọkụ dị elu.Na-emeziwanye microhardness mkpuchi ihe mejupụtara, na-eyi nkwụsi ike na-abawanye ugboro 2-3, meziwanye ndụ ọrụ nke oge 3-5, ike nke mkpuchi na mkpụrụ mụbara site na 40%, ikike mkpuchi siri ike, mkpuchi edo, dị nro ma dị nro;

Ngwa 5 ndị ọzọ: ceramics usoro arụmọrụ dị elu (dị ka nozzle rọketi, ụlọ ọrụ nuklia, wdg), ihe na-amị amị, griiz na-eguzogide ọgwụ, paịlị breeki na-arụ ọrụ dị elu, ike siri ike, iyi nguzogide nke mkpuchi ntụ ntụ, seramiiki mejupụtara seramiiki na-eme ka ike sie ike. , wdg;N'ọhịa nke ihe owuwu ụlọ ọrụ ikuku, mkpuchi na-arụ ọrụ, mkpuchi nchebe, ihe na-adọrọ adọrọ, ihe nzuzo, wdg;Tankị na ụgbọ ala ndị agha na-ebu agha nchebe;Maka ngwá ọrụ ịkpụ seramiiki, ngwá ọrụ ịkpụ na ihe atụ ma nwụọ;Dị ka ihe pụrụ iche eji structural ceramics, arụ ọrụ ceramik, engineering ceramik;Mgbanye ọkụ;Ihe na-ekpo ọkụ ọkụ eletrik ụlọ ọrụ mmepụta ihe, terere infrared generator.

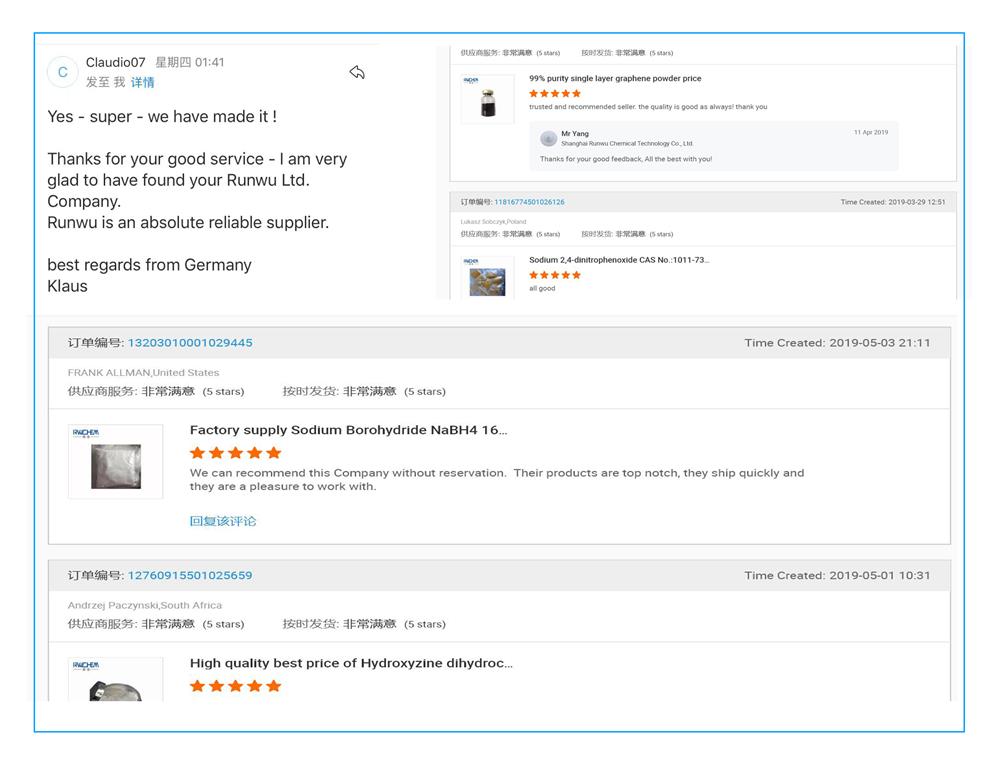

Shanghai Runwu Chemical Technology Co. Ltd bụ ngwaahịa ụlọ ọrụ kemịkalụ R & D, mmepụta, ahịa, dị ka otu n'ime nchọpụta.Anyị na-adabere na ike nyocha ike na nkà na ụzụ tozuru okè, na-enwe ọganihu ngwa ngwa na ụlọ ọrụ kemịkalụ, na-adabere na nkà mmụta sayensị na nkà na ụzụ mmepe, iji nye ndị ahịa ngwaahịa dị elu bụ nchụso anyị mgbe niile.

Anyị tumadi emeso organic intermediates, mma metal catalyst, nano ihe, obere ụwa.A na-eji ihe ndị a eme ihe na kemistri, ọgwụ, bayoloji, nchekwa gburugburu ebe obibi, ume ọhụrụ, wdg.

Site na ogo ngwaahịa nke mbụ na ọrụ nka mara mma, Anyị enwetala otuto nke kọstọm.N'otu oge ahụ, na mmepe, anyị ụlọ ọrụ rube isi na imekọ ihe ọnụ na anụ ụlọ na mba ọzọ ụlọ ọrụ, na nkà mmụta sayensị nnyocha ụlọ ọrụ, mahadum mgbanwe, iji melite R & D na mmepụta ikike, kpebisiri ike na-enye ndị ahịa na ndị ọzọ àgwà ngwaahịa na ọrụ.

Ihe atụ efu

Ihe nlele efu maka nleba anya dị mma

Ụlọ ọrụ mmepụta ihe

Nnabata nyocha ụlọ ọrụ

Nye iwu

Obere usoro anabatara