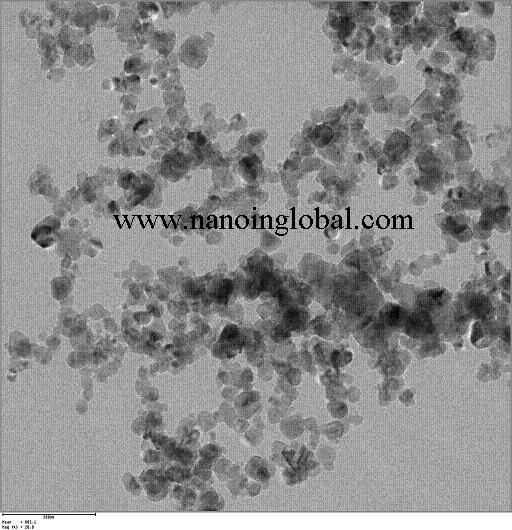

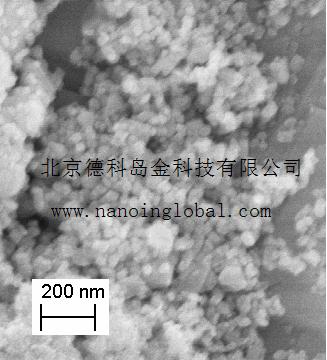

Technical parameters Products are classified | Model | Average particle size (nm) | Purity (%) | Specific surface area (m 2/ g) | Bulk density (g / cm 3) | Polymorphs | Color | Nanoscale | DK-SiC-001 | 40 | > 99.9 | 39.8 | 0.11 | Cube | Celadon | Submicron | DK-SiC-002 | 600 to 800 | > 99.5 | 3.20 | 1.52 | Cube | Shallow white |

The main features of nanometer silicon carbide, ultra-fine silicon carbide powder prepared through a special process with high purity, small particle size distribution range, high specific surface area; nano silicon carbide has a stable chemical properties, high thermal conductivity (165W/MK), the coefficient of thermal expansion small, high hardness, Mohs hardness of 9.5, microhardness 2840 ~ 3320kg/mm2 First of all the materials wear additives, its hardness between corundum and diamond, the mechanical strength is higher than corundum; nano silicon carbide has excellent thermal conductivity, or a semiconductor, high temperature anti-oxidation; nano silicon carbide wear-resistant, high temperature resistance, corrosion, acid and alkali solvent, widely used in paints, paint the inside, increase the wear resistance.

Applications

A modified high-strength nylon materials: nano-SiC powder in the polymer composites have good compatibility, good dispersion, and the substrate, the modified high-strength nylon alloy tensile strength than ordinary PA6 increased by 150% , wear resistance increased by more than three times.Mainly used for armored tracked vehicles polymer parts, steering parts, textile machinery, mining machinery, linings, train parts can achieve at a lower temperature sintering densification;

Modification of special engineering plastics polyether ether ketone (PEEK) wear resistance: nano silicon carbide surface treatment after the company, adding 5% or so, can greatly improve and enhance the wear resistance of PEEK and (to improve the original more than 30%);

3 nm silicon carbide in the rubber tire: nano silicon carbide, add about 2% under the premise does not change the original glue formula modification, without compromising its original performance and quality, the wear resistance can be increased by 20% -40%. In addition, the 40 nm silicon carbide used in the rubber roller, printer fuser film wear, heat, temperature and other rubber products;

4 metal surface nano-SiC composite coating: mixed particles of nanoscale particles, nickel matrix metal, the metal surface to form a high density, binding very good electrodeposited composite coating, the metal surface with super-hard (wear ) and antifriction self-lubricating high temperature characteristics. Microhardness of the composite coating greatly improve the wear resistance is increased by 2-3 times, the service life increased by 3-5 times, the coating and the substrate binding capacity increased by 40%, coverage ability, uniform coating, smooth, detailed;

Five other applications: high-performance structural ceramics (such as rocket nozzles, nuclear industry, etc.), absorbers, anti-wear grease, high-performance brake pads, high hardness and wear-resistant powder coating, ceramic composite strengthening and toughening, etc.; aerospace industry the structure of coating, functional coating, protective coating, absorbing materials, stealth materials, etc.; the protective armor of tanks and armored vehicles; for ceramic cutting tools, cutting tools, measuring tools, molds; can be used for special purposes of structural ceramics, functional ceramics, Engineering Ceramics; ignition; electrical heating elements for industrial use, far infrared generator.

|