|

Products are classified

|

Model

|

Average particle size (nm)

|

Purity (%)

|

Specific surface area (m 2 / g)

|

Bulk density (g / cm 3)

|

Polymorphs

|

Color

|

|

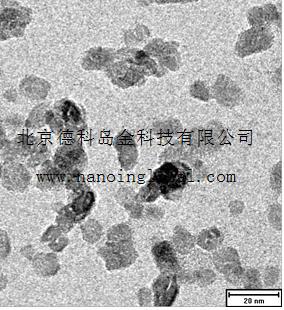

Nanoscale

|

DK-Al-001

|

50

|

> 99.9

|

20

|

0.23

|

Globular

|

Black

|

|

Submicron

|

DK-Al-002

|

800

|

> 99.9

|

2

|

1.50

|

Globular

|

Silver

|

Main characteristics of nano-aluminum, ultra-fine aluminum powder prepared through a special process, high purity, spherical high impurity content of active aluminum accounted for more than 98%, yield, size distribution, surface area of high activity, easy to disperse use resin, rubber and other polymer materials.

Applications

An efficient catalyst: nano-aluminum powder added to the solid fuel rocket, greatly improve the speed of fuel combustion to improve combustion stability;

Activated sintering additives: AlN powder mixed with 5 to 10% nano-aluminum body to reduce the sintering temperature, sintered density and thermal conductivity; nano-aluminum integrated components of the substrate, the thermal conductivity about 10 times, can be solve the integrated components of integration.

Conductive surface coating of the three metals and scrap metal processing: nano-aluminum activated surface temperature below the powder melting point coating, under anaerobic conditions, this technique can be applied to the production of microelectronic devices.

Four widely used high-grade metal paint, composite materials (thermal spraying composite metal powder, ceramic composite steel pipe) military (filler), chemical (various catalysts, pesticides), metallurgy (aluminum thermal metallurgy steelmaking Deoxidizer), shipbuilding (conductive coating), refractory materials (steel-making furnaces, magnesia carbon bricks), new building materials (aerated concrete made gas agents), anti-corrosion materials, fireworks, and so on.

Technical support company can provide nano-aluminum, ultra-fine aluminum powder in the thermal conductivity of resin, paint additives, powder metallurgy technology support, and specific application information, please contact the sales department personnel.

Packaging, storage product is inert gas anti-static packaging, should be sealed and stored in a dry, cool environment, should not be long exposed to the air, anti-moisture group influence in sub-s Scattered performance

|