|

Technical parameters

|

Products are classified

|

Model

|

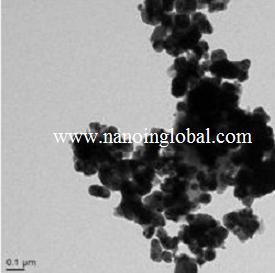

Average particle size (nm)

|

Purity (%)

|

Specific surface area (m 2/ g)

|

Bulk density (g / cm3)

|

Polymorphs

|

Color

|

|

Nanoscale

|

DK-Si 3 N 4-001

|

20

|

> 99.9

|

59.6

|

0.09

|

Amorphous

|

White

|

|

Submicron

|

DK-Si 3 N 4-002

|

800

|

> 99.5

|

10.3

|

1.16

|

Face-centered cubic

|

Gray

|

|

High-purity grade

|

DK-Si 3 N 4-003

|

800-1000

|

> 99.99

|

9.80

|

1.20

|

Face-centered cubic

|

Gray

|

The main characteristics of nano-silicon nitride ultrafine silicon nitride powder prepared by a special process method, high purity, small particle size, distribution, large surface area, surface activity, low bulk density, UV reflection rate of 95% and absorption of infrared absorption rate above 97%, the device into a porcelain low temperature, good dimensional stability, high mechanical strength, resistance to chemical corrosion, high temperature strength, and self-lubricating effect in the composite in the formation of fine dispersed phase, thus greatly improving the overall performance of composite. Its products with self-lubricating properties, can be applied to the oil. The high hardness of silicon nitride, the coefficient of sliding friction characteristics can be applied to the metal surface of ceramic wear-resistant composite coatings, applied to the coatings can play a wear-resistant and solvent characteristics, high-purity silicon nitride can be used in a quartz crucible release agent with.

Applications

The manufacture of structural devices: such as ball and roller of the rolling bearings used in the metallurgical, chemical, machinery, aviation, aerospace and energy industries, plain bearings, sleeve, valve, and wear, high temperature resistance, corrosion resistance requirements for the structure devices. rocket nozzles, missile with nozzle;

Metals and other materials surface treatment: such as molds, cutting tools, turbine blades, turbine rotor and the cylinder wall coating alloy;

3 composite materials: metals, ceramics, and graphite-based composites, rubber, plastics, coatings, adhesives and other polymer-based composites;

4 wear self-lubricating nanoparticle films for mobile phones, cars and other surface protection, wear-resistant coating, electrophoresis paint additives, play a high abrasion characteristics.

|