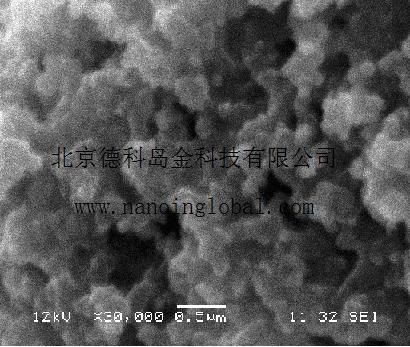

Wholesale Price China Nano Graphite Powder - W 50nm 99.9% – Runwu Detail:

W 50nm 99.9% | |||||||||||||||||||||||||

|

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for Wholesale Price China Nano Graphite Powder - W 50nm 99.9% – Runwu, The product will supply to all over the world, such as: Mumbai , Iceland , Algeria , We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

-

Best quality 2 5-Dimethyl Furan - N-Hydroxysul...

-

China wholesale Nano Zinc Powder - Al 50nm 99....

-

Factory Outlets Benzyl Alcohol 98% - Times New...

-

Chinese Professional Octenylsuccinic Anhydride ...

-

Wholesale Price China Nano Graphite Powder - S...

-

2019 Good Quality Nano Silicon Nitride - Al2O3...